REALTIME FLOWS  U. Kern: n/a cfs

U. Kern: n/a cfs

L. Kern: 1341 cfs

L. Kern: 1341 cfs

E.W: 312 cfs

E.W: 312 cfs

U. Owens: 108 cfs

U. Owens: 108 cfs  L. Owens: 496 cfs 09/02/19 1:15 PM PST

L. Owens: 496 cfs 09/02/19 1:15 PM PST

Welded Loops and Leader Connections

55 posts

• Page 2 of 4 • 1, 2, 3, 4

Re: Welded Loops and Leader Connections

I use some new looped lines and haven't had any problems; I have most with loop to loop using mono nail knotted to the leader and that works fine.

But I do have a suggestion if you have problems with any of the setups going through the guides, especially when they are hung up and the fish is pulling line out, turn your rod reel up and the connnections will go out of the rod much more smoothly. I mostly use this technique when float tubing, and I'm having problems getting a fish close enough to net.

Mark

But I do have a suggestion if you have problems with any of the setups going through the guides, especially when they are hung up and the fish is pulling line out, turn your rod reel up and the connnections will go out of the rod much more smoothly. I mostly use this technique when float tubing, and I'm having problems getting a fish close enough to net.

Mark

- meb

- Posts: 325

- Joined: November 7th, 2008, 2:36 pm

- Location: OC

Re: Welded Loops and Leader Connections

Just a couple real world(what ever that is)experiences with loops. This doesn't speak to anything, but how strong some are.

I've broken 2 fly lines on snags, that had loops. One was a brand new, SA Mastery, Bass Bug with factory welded loop. The line broke about 6" below the loop. I do not know what the factory loop looked like after I pulled hard enough to break the line....because it was still hanging up in a tree. Second one was a T14 shooting head. I installed my own 50lb, braided mono loops on it. The leader end broke. I think the line broke behind the loop, but I can't be sure. There was no sign or marks of slippage on the head. Done right, both types of loops are at least as strong as the core of the fly line.

Second one was a T14 shooting head. I installed my own 50lb, braided mono loops on it. The leader end broke. I think the line broke behind the loop, but I can't be sure. There was no sign or marks of slippage on the head. Done right, both types of loops are at least as strong as the core of the fly line.

You have to pull really hard to break a fly line. Most have a 30 lb core(some less, and some more). I've also stripped the outer coating off a fly line, by having a nail knotted butt section strip the outer coating. It took considerably less pulling to have that connection fail, but it still takes a lot of pressure to get it to fail. This morning I pulled very hard to break 2X(Seaguar Grand Max 12.5lb) off of a snag. It was a Rio Gold line with factory wielded loop. While I had to exert quite a bit of pressure, the thought of the loop failing didn't even enter my mind. Later I switched leaders, and there wasn't even a cut in the loop.

briansII

I've broken 2 fly lines on snags, that had loops. One was a brand new, SA Mastery, Bass Bug with factory welded loop. The line broke about 6" below the loop. I do not know what the factory loop looked like after I pulled hard enough to break the line....because it was still hanging up in a tree.

You have to pull really hard to break a fly line. Most have a 30 lb core(some less, and some more). I've also stripped the outer coating off a fly line, by having a nail knotted butt section strip the outer coating. It took considerably less pulling to have that connection fail, but it still takes a lot of pressure to get it to fail. This morning I pulled very hard to break 2X(Seaguar Grand Max 12.5lb) off of a snag. It was a Rio Gold line with factory wielded loop. While I had to exert quite a bit of pressure, the thought of the loop failing didn't even enter my mind. Later I switched leaders, and there wasn't even a cut in the loop.

briansII

-

briansII - Posts: 4902

- Joined: September 3rd, 2008, 12:39 pm

- Location: Central Ca.

Re: Welded Loops and Leader Connections

Rob909 wrote:I am in the marker for some new fly lines and trying to decide what to do with the welded loops that most lines come with nowadays.

In the past I have cut them off and attached my leader to my fly line with a needle knot, and when I need to change my leader I just cut off the old one and attach a new one to my fly line. And I have done this because I hate getting loop to loop connections up in my guides. It drives me crazy.

But what I am starting to notice is that after multiple leader changes and shortening of the line, I am past the 6-7” inch tip section of the line and moving into the functional part of the line. I feel like this is affecting the way the line is working.

I have considered a 10” butt section and then a blood knot connection to the leader, then when I have to change the leader I’m just trimming the butt section……no big deal. But I am terrible at blood knots!!!!! Maybe this is the real problem

So I was wondering what everyone else does, what works best for them and such.

Thanks in advance.

Rob

I think a double surgeon knot could solve your problem if you're having troubles tying a blood knot. It's a simple knot strong and I never had a failure.

Right now on all my various setups (4 weight all the way up to a 12 weight) I have welded loops, braided loops and home made loops. All have worked fine with no failures yet. I have to say my least favorite would be a nail knot to a butt section but I fished that for a long time as well on my 4 weight. I never had a failure but it was the only connection I would constantly check before an outing. Braided is probably the simplest and user friendly so If I have the right size loop available I would probably go with a braided loop first. I do always back it up with a small nail knot at the end of the connection.

I would think on your basic trout lines (5 wt and under) the problem with any kind of connection failure whether it be manufacturer or your own is moot. Since the failing point of your standard Trout tippet is 3 to 5 pounds that's going to be under the failing point of any welded, braided or nail knot/butt section.

Working your way offshore using 20 pound tippets the strength of your connection is more of a consideration. For offshore I make my own braided loops and apply multiple nail knots over the braid. I have had fly lines break before the connection on a braided loop (with back up nail knots) so I consider them very strong.

Using your criteria of not liking the loop going through your guides I would suggest you use the nail knot/butt section tapered with double surgeon knots or try a braided loop connection. jon

Somebody just back of you while you are fishing is as bad as someone looking over your shoulder while you write a letter to your girl.

Ernest Hemingway

Ernest Hemingway

-

hip - Posts: 445

- Joined: August 26th, 2009, 1:12 pm

Re: Welded Loops and Leader Connections

I find the welded loops work just fine, until the line cracks beneath the weld. Then it's the old snip, snip. Nail knot a stiff, say 20 lb. piece of mono, often from the butt end of an old leader, to the line and tie a perfection loop in it. I try to keep this connector just under 4 inches in length.

Actually though, the only one of the loop methods I've seen fail is the braided connector. Actually, it was on a line and reel I'd sold to a friend. He was dredging the bottom of a deepish plunge pool and the current sucked his flies into some boulders. While trying to pull flies loose, the line shot back at him. Upon checking, it turned out the braided connector had slipped off. To this day I no longer trust the things. I'll never use them again.

Actually though, the only one of the loop methods I've seen fail is the braided connector. Actually, it was on a line and reel I'd sold to a friend. He was dredging the bottom of a deepish plunge pool and the current sucked his flies into some boulders. While trying to pull flies loose, the line shot back at him. Upon checking, it turned out the braided connector had slipped off. To this day I no longer trust the things. I'll never use them again.

How do you tie the fly to your hooks without killing them with the thread? I keep cutting them in half.

-

darrin terry - Posts: 3369

- Joined: July 26th, 2008, 8:47 am

- Location: Locale: NoCal

Re: Welded Loops and Leader Connections

Darrin Terry wrote:I find the welded loops work just fine, until the line cracks beneath the weld. Then it's the old snip, snip. Nail knot a stiff, say 20 lb. piece of mono, often from the butt end of an old leader, to the line and tie a perfection loop in it. I try to keep this connector just under 4 inches in length.

Actually though, the only one of the loop methods I've seen fail is the braided connector. Actually, it was on a line and reel I'd sold to a friend. He was dredging the bottom of a deepish plunge pool and the current sucked his flies into some boulders. While trying to pull flies loose, the line shot back at him. Upon checking, it turned out the braided connector had slipped off. To this day I no longer trust the things. I'll never use them again.

Darrin was that a straight braided loop or was it backed up with a nail knot?

Thanks jon

Somebody just back of you while you are fishing is as bad as someone looking over your shoulder while you write a letter to your girl.

Ernest Hemingway

Ernest Hemingway

-

hip - Posts: 445

- Joined: August 26th, 2009, 1:12 pm

Re: Welded Loops and Leader Connections

Braided loop to loop connectors are all about the installation. Don't install them correctly and they will eventually pull off. I have never had one pull off yet and I have been using them for years. That being said, several years ago I heard all the horror stories about them pulling off and started using either a drop of super glue or knot sense as an extra precaution.

-

Pete - Posts: 840

- Joined: May 28th, 2009, 12:30 pm

- Location: Central Coast of Ca.

Re: Welded Loops and Leader Connections

This one had superglue added, but no nail knot. I also did not like its tendency toward picking up moss and it tendency to sink. Hated having to pack it with floatant, too. I'll grant that it would not likely have failed on a fish, as no trout could have pulled as hard as he could against a snag. Always been surprised that the leader did not snap first on that one.

How do you tie the fly to your hooks without killing them with the thread? I keep cutting them in half.

-

darrin terry - Posts: 3369

- Joined: July 26th, 2008, 8:47 am

- Location: Locale: NoCal

Re: Welded Loops and Leader Connections

What is wrong with all of you people? Haven't you ever heard of double taper lines or square knots? Helloooooo! Here is what you should be doing: use only double taper line. Cut any loops off of it and off of any leaders you buy. Tie the leader to the fly line with a square knot (right over left, left over right). If you lose some of the skinny part of the leader while fishing, cut the whole thing off and just tie on a new leader. Tippet is overrated and overpriced. I usually go a few inches up the fly line to make a clean cut. Now, you keep doing this until you have cut away about half of your fly line, when that happens, you take it off of the reel and turn it around. That's why it's double taper (duh!) It's so that when you've used half of it you can turn it around. Sheesh.

No loops, no blood knots, surgeon's knots, no muss no fuss. Just square knots and fly line. Oh, and when you run out of the second half of the fly line, don't buy a new one. Just use that backing instead; it makes a great sinking line! Oh, and if any so-called fly fishing "expert" ever asks where you heard this advice, no need to give me credit. I'm much too modest and humble for that. Just tell them that you read it in an Orvis catalog or something.

No loops, no blood knots, surgeon's knots, no muss no fuss. Just square knots and fly line. Oh, and when you run out of the second half of the fly line, don't buy a new one. Just use that backing instead; it makes a great sinking line! Oh, and if any so-called fly fishing "expert" ever asks where you heard this advice, no need to give me credit. I'm much too modest and humble for that. Just tell them that you read it in an Orvis catalog or something.

Nature always wins.

> miles = < people

Camp in the mountains, not the left lane!

> miles = < people

Camp in the mountains, not the left lane!

-

Papasequoia - Posts: 4655

- Joined: July 5th, 2008, 10:14 pm

- Location: East Side of the Sierra Nevada

Re: Welded Loops and Leader Connections

Papasequoia wrote:What is wrong with all of you people? Haven't you ever heard of double taper lines or square knots? Helloooooo! Here is what you should be doing: use only double taper line. Cut any loops off of it and off of any leaders you buy. Tie the leader to the fly line with a square knot (right over left, left over right). If you lose some of the skinny part of the leader while fishing, cut the whole thing off and just tie on a new leader. Tippet is overrated and overpriced. I usually go a few inches up the fly line to make a clean cut. Now, you keep doing this until you have cut away about half of your fly line, when that happens, you take it off of the reel and turn it around. That's why it's double taper (duh!) It's so that when you've used half of it you can turn it around. Sheesh.

No loops, no blood knots, surgeon's knots, no muss no fuss. Just square knots and fly line. Oh, and when you run out of the second half of the fly line, don't buy a new one. Just use that backing instead; it makes a great sinking line! Oh, and if any so-called fly fishing "expert" ever asks where you heard this advice, no need to give me credit. I'm much too modest and humble for that. Just tell them that you read it in an Orvis catalog or something.

Papa do those double taper lines come with welded loops on both ends? I'm no good at square knots.

Andy

-

DubL HauL - Posts: 1154

- Joined: July 27th, 2008, 5:07 pm

Re: Welded Loops and Leader Connections

For crying out loud, Andy. They say that there are no dumb questions, but you are getting close. OK, I am going to take a deep breath and try to explain this slowly for you. If you have problems with a square knot, you make your own welded loops streamside, the old-fashioned way. Throw away those stupid water bottles, the little pouch on the side of fishing packs isn't for water bottles, it's for small torches so that you can quickly and easily make your welded loop if you are one of those people who can't tie a square knot.

However, if you can't tie the square knot you might also try the single surgeon's knot, it's a doozy, especially for tippet to fly!

This has been a public service message brought to you by Giardia Inc.

PS Some interesting information in this thread (besides mine), I wouldn't have hijacked it if it hadn't looked like it had run its course. But, if anyone has more serious info to add, please do...and just ignore that man behind the curtain cracking jokes.

However, if you can't tie the square knot you might also try the single surgeon's knot, it's a doozy, especially for tippet to fly!

This has been a public service message brought to you by Giardia Inc.

PS Some interesting information in this thread (besides mine), I wouldn't have hijacked it if it hadn't looked like it had run its course. But, if anyone has more serious info to add, please do...and just ignore that man behind the curtain cracking jokes.

Nature always wins.

> miles = < people

Camp in the mountains, not the left lane!

> miles = < people

Camp in the mountains, not the left lane!

-

Papasequoia - Posts: 4655

- Joined: July 5th, 2008, 10:14 pm

- Location: East Side of the Sierra Nevada

Re: Welded Loops and Leader Connections

Actually the real reason for going with welded loops is because 95% of fly fishers don't even know how to attach a leader to a flyline via a simple nail knot!!!!! Really, that's true!!!!

And in most instances, the cracking that occurs in most welded loops is "nuisance" cracking in the outer PVC coating. As long as the core is intact (typically the braided core does not crack) there is no significant strength loss in the break strength of the line.

First generation welded loops indeed had a high rate of failure. All manufacturers now have it down pretty good, so past claims are of breaking are now not an issue.

Once the line core cracks I have no qualms about chopping the welded loop off. But, I have three years of hard Alaska fishing on my Rio Nymph line; landing salmon, trout, and steelies up to 15 pounds and it's still in great shape.

And in most instances, the cracking that occurs in most welded loops is "nuisance" cracking in the outer PVC coating. As long as the core is intact (typically the braided core does not crack) there is no significant strength loss in the break strength of the line.

First generation welded loops indeed had a high rate of failure. All manufacturers now have it down pretty good, so past claims are of breaking are now not an issue.

Once the line core cracks I have no qualms about chopping the welded loop off. But, I have three years of hard Alaska fishing on my Rio Nymph line; landing salmon, trout, and steelies up to 15 pounds and it's still in great shape.

- NorcalBob

- Posts: 1620

- Joined: March 2nd, 2009, 9:27 pm

Re: Welded Loops and Leader Connections

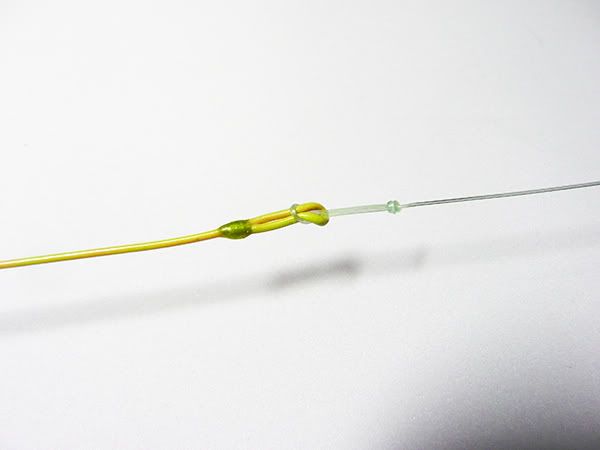

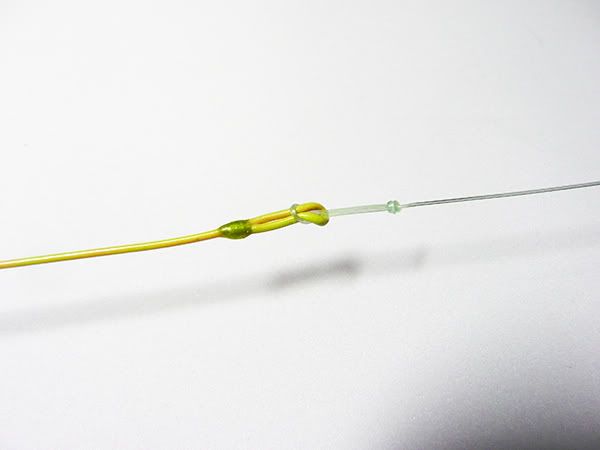

i've tried a lot of different connections. this is what i'm using for now.

my own welded loop. on Orvis Wonderline, which btw i am not too fond of. welded loop cracked 2nd time around, had to nail knot a butt section, then just decided to make my own loop. I have done this on my 3wt line and 1wt line. My RIO Nymph line hasn't had any problems with the welded loop so far, and I use a braided loop on my 6wt. The system i use now is my welded loop to 6" of Orvis HyFlote butt material to leader. butt section is loop to loop to the leader using perfect loop knot. I think I liked the butt nail knot to the leader better, i'll probably switch back to that once i start tossing dries more often again.

my own welded loop. on Orvis Wonderline, which btw i am not too fond of. welded loop cracked 2nd time around, had to nail knot a butt section, then just decided to make my own loop. I have done this on my 3wt line and 1wt line. My RIO Nymph line hasn't had any problems with the welded loop so far, and I use a braided loop on my 6wt. The system i use now is my welded loop to 6" of Orvis HyFlote butt material to leader. butt section is loop to loop to the leader using perfect loop knot. I think I liked the butt nail knot to the leader better, i'll probably switch back to that once i start tossing dries more often again.

-

gabe - Posts: 553

- Joined: August 4th, 2008, 3:18 pm

- Location: SoCal

Re: Welded Loops and Leader Connections

Looks clean gabe, but what exactly did you do? what is the procedure? I would like to do this to replace the welded loop on my SA line that is cracked.

Fishing is the most wonderful thing I do in my life, barring some equally delightful unmentionables.

http://www.adiposefin.com

http://www.adiposefin.com

-

rayfound - Posts: 2401

- Joined: September 11th, 2008, 11:11 pm

- Location: Riverside, ca

Re: Welded Loops and Leader Connections

rayfound wrote:Looks clean gabe, but what exactly did you do? what is the procedure? I would like to do this to replace the welded loop on my SA line that is cracked.

all i did was secured the loop with a nail knot. I just used tippet, coated with cement or knot sense.

oh i cut the tag end of the loop at an angle, and wrapped down past the tag.

-

gabe - Posts: 553

- Joined: August 4th, 2008, 3:18 pm

- Location: SoCal

Re: Welded Loops and Leader Connections

Before we go any further, I'll warn you that we are entering the loop geekdom zone.

A whipped loop.

Welded loop.

Here's a couple methods I think are nicer.

http://www.nwsalmonflyguild.org/inst/We ... 20Loop.pdf

http://www.hooked4life.ca/glsteelhead/M ... Loops.html

Making, and installing braided loops.

IMHO, the above method of making and installing braided loops, is far superior(in strength)to using a shrink wrap sleeve over the end of the braided mono. He didn't show using a glue to smooth over the nailknot, but you can/should.

briansII

A whipped loop.

Welded loop.

Here's a couple methods I think are nicer.

http://www.nwsalmonflyguild.org/inst/We ... 20Loop.pdf

http://www.hooked4life.ca/glsteelhead/M ... Loops.html

Making, and installing braided loops.

IMHO, the above method of making and installing braided loops, is far superior(in strength)to using a shrink wrap sleeve over the end of the braided mono. He didn't show using a glue to smooth over the nailknot, but you can/should.

briansII

-

briansII - Posts: 4902

- Joined: September 3rd, 2008, 12:39 pm

- Location: Central Ca.

55 posts

• Page 2 of 4 • 1, 2, 3, 4

Who is online

Users browsing this forum: Google [Bot] and 76 guests